Crane Upgradation Service

Product Details:

X

Product Description

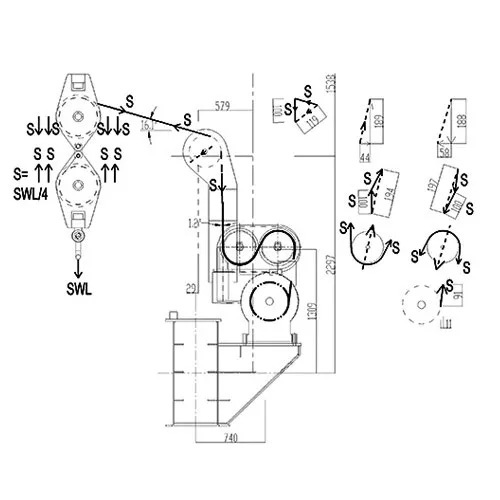

Our crane upgrade service is a specialized service offered by our company that maintains and improves the functionality of existing cranes. The process of upgrading includes changing out worn-out parts, upgrading motors and drives, or even strengthening the structure of the crane. This may result in higher lifting capacities, quicker lifting rates, and enhanced performance all around. Upgrading can increase the lifespan of your crane and save you money on buying a new one by addressing wear and tear and replacing essential components. For increased accuracy and efficiency, it replaces antiquated electrical systems with contemporary AC drives and control panels.

Certified Expertise for Reliable Upgradation

Our team consists of qualified crane technicians and engineers who possess advanced certifications and extensive experience. Each upgradation is performed adhering strictly to industry safety protocols, ensuring your cranes meet the latest IS and OSHA standards for quality and reliability.

Tailored Solutions with Seamless System Integration

We understand every operation is unique. That's why our upgradation approach is thoroughly customized and includes the integration of your crane systems with state-of-the-art automation and monitoring technologies. This modernization not only streamlines operational efficiency but also enables comprehensive tracking and control for industrial and commercial applications.

FAQ's of Crane Upgradation Service:

Q: How does the crane upgradation process work?

A: The upgradation process starts with a site assessment by our certified engineers. They evaluate your existing crane systems and design a customized upgradation plan, covering retrofitting, control modernization, and capacity enhancement. The service is performed on-site, followed by rigorous testing and documentation.Q: What safety standards are followed during upgradation?

A: All upgradation projects adhere to the latest Indian Standards (IS) and OSHA safety requirements. Our team implements strict protocols throughout each phase, ensuring enhanced safety and compliance for all crane types.Q: When can I expect the upgradation to be completed?

A: The service duration depends on the scope of your project, crane type, and specific requirements. After assessment, we provide a definitive timeline aligned with your operational schedules to minimize downtime.Q: Where is the upgradation service available?

A: Our crane upgradation solutions are offered pan India. Regardless of your industry location, our team can deliver on-site upgrades, serving industrial and commercial sites across the country.Q: What documentation will I receive after upgradation?

A: You'll be provided with comprehensive reports detailing all upgradation activities, quality checks, and testing outcomes. This documentation supports compliance and offers reference for future maintenance.Q: How does system integration benefit my crane operations?

A: Integrating cranes with advanced automation and monitoring systems improves operational control, enhances safety, and facilitates predictive maintenance. This modernization ensures your equipment delivers optimal performance and reliability.Q: What maintenance support is available post-upgradation?

A: We offer dedicated maintenance plans after upgradation. These plans include regular inspections, preventive maintenance, and prompt technical assistance to keep your upgraded crane systems functioning efficiently.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email